About Us

ADTEC was established in

Number of patents obtained

Global Service Outlets

Since its establishment in January 1985, the tenet of our company is "trust" and "fast (quality = quality, innovation = innovation, creativity = creativity, good at the earth environment"). On this basis, we sell and manufacture high-frequency radio frequency power supplies, automatic impedance matching devices and related products with high reliability for semiconductor and liquid crystal industries, and strive to establish basic technology and challenge cutting-edge technology.

In the future, we will enhance the capabilities of our sales and service bases in Europe, the United States and Asia to enhance our high value-added product lineup, thereby pooling the strength of the ADTEC Group and addressing the increasingly important overseas markets.

The applicability of advanced plasma technology

Plasma technology is essential for enriching our future, such as the miniaturization of televisions and mobile phones, the enhancement of functions in household appliances around us, and automotive autonomous driving systems.

Our plasma technology can be used in the rapidly evolving fields of semiconductor manufacturing and LCD manufacturing. We are also committed to developing new products using plasma technology.

Integrated production system within the group

This belief has been upheld since the company's inception, utilizing industry-leading technology and assembly techniques, from equipment manufacturing/tool development to factory management.

The management of mass production processes is consistently conducted within the group company.

Technical capabilities that can meet a wide range of needs

We offer a variety of power supply products based on your needs.

We also focus on flexible designs to meet real needs and are working to strengthen the system.

Technical Proposal Function

We will make full use of the manufacturing knowledge and experience accumulated so far, and provide more services and suggestions for your consultation than you requested, such as 'reducing costs', 'shortening delivery times', and 'providing new technologies'.

Global comprehensive support system

In order to establish a globally renowned 'ADTEC' brand and to ensure that customers can use our products with confidence, we will provide customer support worldwide and conduct business together with customers from all over the world.

-

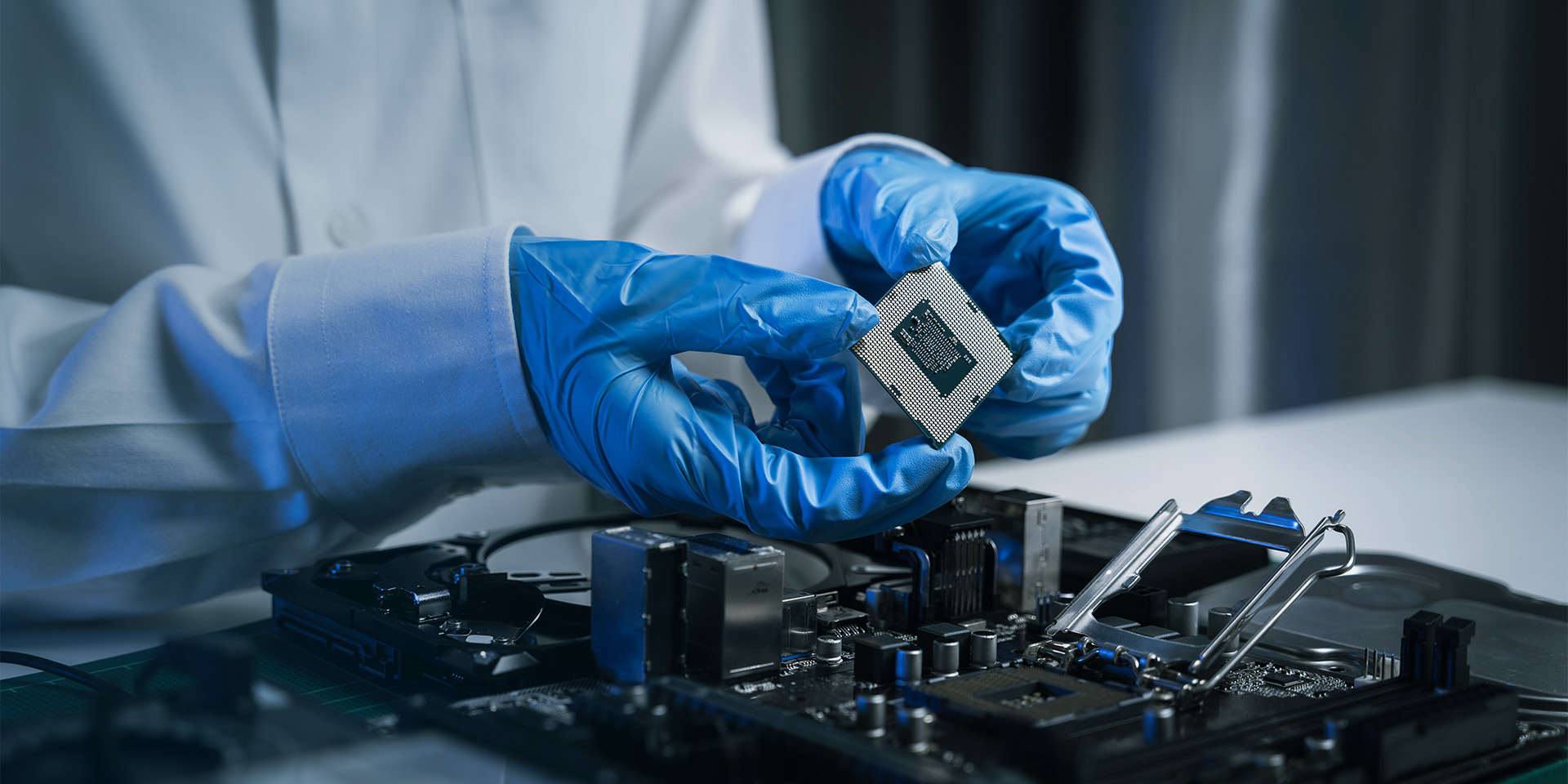

Semiconductor

Learn moreSemiconductors are a special type of material that lies between conductors and insulators, possessing unique electronic properties. Their conductivity can change with variations in external conditions, such as temperature and light. In the modern electronics industry, semiconductors play a core role and are widely used in fields such as integrated circuits, transistors, and solar cells.

Semiconductor -

Photovoltaic

Learn morePhotovoltaics is a green energy technology that converts solar energy into electrical energy. It is based on the photovoltaic effect, using solar panels to convert sunlight into direct current. This technology has many advantages, such as being a renewable energy source, noiseless, and pollution-free. As the global demand for renewable energy continues to grow.

Photovoltaic -

Electromechanical

Learn moreMechatronics is a comprehensive discipline that encompasses the fields of mechanical and electronic technology. It combines mechanical principles, electronic technology, and computer technology to achieve automation, intelligence, and efficiency in equipment.

Electromechanical

Follow Adetec Plasma Technology for more information

Introduction, characteristics, and applications of high-frequency machinery

2024-12-26

High-frequency induction heating equipment is the key to metal heating.

2024-12-26